Van racking can boost efficient operation as well as improve vehicle safety, says Dan Gilkes.

Purpose-built racking and storage systems for light commercial vehicles have become an increasingly essential component in the overall build of a new van for many fleets. Simply throwing parcels, materials and tools into the back of a van can be dangerous and inefficient, though there are many companies that still do just that.

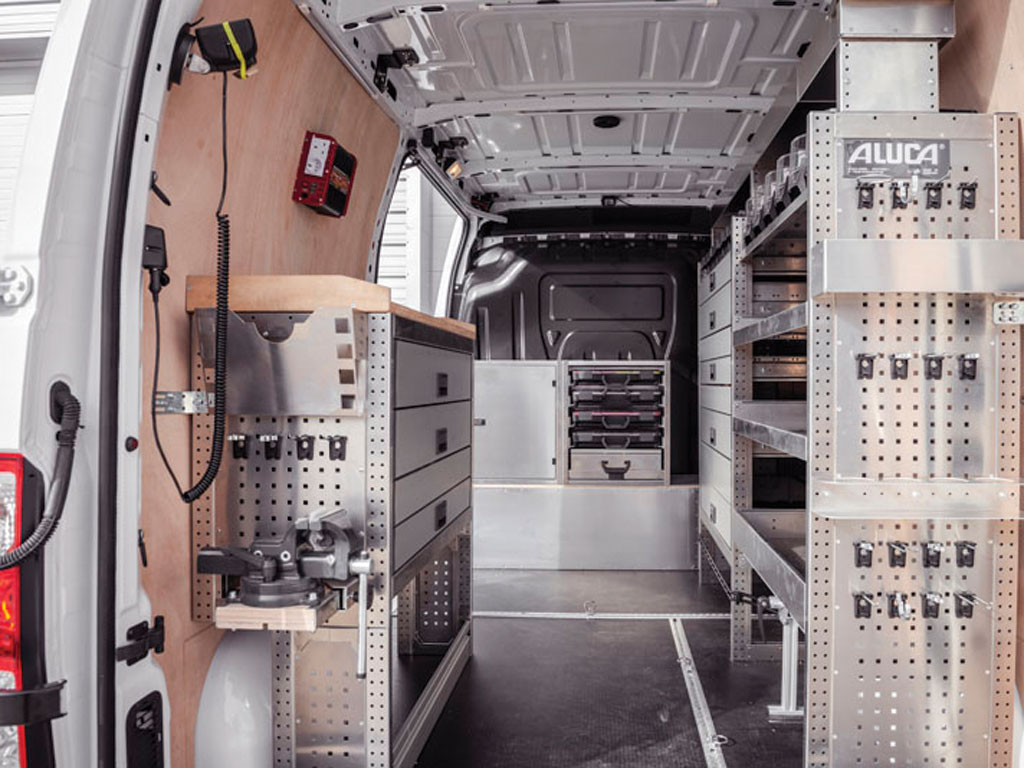

Properly designed and crash-tested racking systems, both internal and external, provide van operators with a safe method of carrying goods and tools, with less risk of harm, both to the vehicle and to its occupants, in the event of an accident. Racking manufacturers can also easily demonstrate the efficiency benefits of decent storage systems.

When a tradesperson such as a plumber spends five minutes at every visit searching through the van for tools or spare parts, that lost time can soon add up. If they make six visits each day for instance, that can be 30 minutes lost, or 2.5 hours over a five-day week. Racking can be a financially effective solution.

So, what should you consider when assessing the racking market?

- Plan the installation. What do you need to carry, will it fit on shelves or in drawers, do you need additional specific storage systems within the main shelving, such as plastic drawers or tool boxes?

- Is overall weight a major consideration, can you work with regular steel racking or do you need a lightweight aluminium or composite racking system to keep weight to a minimum and boost payload?

- Check the weight limitations of the racking itself, most manufacturers will publish the weight capacity of shelving, drawers and locker systems. Is it sufficient to carry your heavy tools or materials?

- Can you install the system in-house, or would you be better off using a professional installation business that can plan, assemble and install the complete system, adding vehicle electrics, signwriting and graphics and internal lighting?

- Does the racking layout ensure that the van is loaded in a way that maintains vehicle stability – don’t just have racking on one side of the van holding all of the heavy materials and tools.

- Do you need flexibility, will the racking system be re-used when you change vehicles and can it be reconfigured to work with a range of van models?

There is certainly no shortage of racking suppliers providing a wide range of systems, or types of racking layout. As with any addition to the base vehicle, weight can be an issue for some users, as any increase in van mass will cut into available payload, but there are many lightweight aluminium and composite solutions on offer to minimise this.

Companies such as Sortimo, System Edstrom, Modul-System, Bri-Stor, Bott and Van Guard all offer a broad range of racking solutions, designed to meet the needs of various trades and van operators. Van Guard’s Trade Van Racking range, for instance, is constructed of lightweight aluminium to keep weight down. Every Van Guard unit has passed an ECE Reg 17 crash-test however, to ensure driver safety in an accident.

A simple, modular design makes it easy to change the design to suit different trades and the Trade Van Racking range is easy to move between different van models. Options include shelving dividers, non-slip matting, plastic bins and unit height extensions, to allow fleets to customise the system to suit. Van Guard also offers a wide range of roof bars, roof racks and pipe carriers.

Joining these established players, hardtop and 4×4 accessory specialist Truckman has launched a racking fit-out service, to provide a bespoke storage solution to small fleet managers and sole traders in particular. From racking to vehicle security, graphics and specialist electrics, the conversion service will also provide ply lining, inverters, electrical charging systems and other racking accessories.

Truckman’s Aluca racking range is available for a wide variety of vans and pickups and is claimed to be up to 20% lighter than some competitors. It too has been crash-tested and comes with an eight-year warranty, which should see it used in at least two van generations.

Truckman recently introduced the Decked range of drawer solutions for vans too. Developed in the US, the Decked range was originally introduced for use in pickup beds. However, it has now attracted a number of van operators looking for a similar solution. Truckman has developed the drawer system to work with Ford’s Transit as well as the Ducato, Relay and Boxer vans from Fiat and PSA.

The system has two bed-length drawers that can be rolled out to provide access to tools and equipment. It also comes with four integrated storage bins for smaller items such as fasteners and tools. Made from recycled high-density polyethylene, the Decked system can hold up to 1,000kg on its raised deck, which is supported by a galvanised steel frame.

Self-assembly and installation

While there are undeniably benefits when talking to a racking specialist, to design a system that will work well for a specific application, it is also possible to fit your own racking, using pre-designed no-drill kits. Bott’s Smartvan system is an example that, despite having been fully safety tested, can be installed independently, using the van’s built-in fixing points, so there is no need to drill into a van body or chassis. Smartvan can accommodate options including roof racks, pipe tubes, van vaults and lighting systems too.

A racking and storage solution can involve external elements as well as internal shelving. Rhino Products has recently added a redesigned pipe carrying system, called PipeTube Pro, to its offer. This is the first major update to the firm’s PipeTube pipe, conduit and trunking roof box. It incorporates a PVC lining material to protect against the oxidation of copper pipes with the aluminium of the tube.

Nose cones at the ends of the PipeTube Pro have also been redesigned to improve aerodynamic performance and improve anti-theft performance. The locking mechanism is now housed within the product and there is an O-ring seal to reduce water ingress. PipeTube Pro is available in 2m and 3m lengths with a universal fitting for a range of van makes.

Trades that use a lot of power tools may also be interested in systems such as the Vantainer line-up, from German firm Tanos. Made from aluminium, with a typical system weighing just 50kg, the Vantainer Case System allows trades to store all tools, accessories and consumables in a series of stackable boxes. This means there are less shelves required, providing more space and payload.

Cases can be easily removed, to allow workers to transport tools and materials to the working site and the flexible shelving requires no fixing or drilling of the van to install, making it easy to fit and remove.

Power provision

Many racking providers can handle far more of the vehicle conversion than simply fitting shelving, undertaking signwriting, interior coatings, adding power systems and undertaking electrical engineering. Bri-Stor has developed a mobile power system, called EasiPower, that can be used in both diesel and electrically-powered light commercials.

EasiPower is a 2.5kW lithium battery pack from Clayton Power that can be used to provide 230V and 12V simultaneously, to drive ancillary equipment or electric power tools. Weighing just 28kg, the EasiPower pack can be recharged from the mains, from a solar charger or from the vehicle’s electrical system. A mobile phone application provides remote monitoring of power levels.

Bri-Stor recently demonstrated the system on a Renault Trucks Master Z.E. showing how the charger can be used to operate electrical tools without depleting an electric van’s traction batteries. The power pack can also be removed from the van to provide remote electrical power, for site operatives and trades.

Buying trends

If you don’t have the facilities to self-install, racking specialists are not the only suppliers that customers can turn to. The majority of van dealers will either be able to call upon a racking firm’s services through their own workshops, or the van manufacturer may provide basic racking systems as part of its accessories offer.

One of the benefits of using the dealer or the van manufacturer to provide the racking directly, is that in most cases it should then be possible to include that additional equipment as part of the van purchase or finance deal. This spreads the cost and ensures that the system in use conforms to the van manufacturer’s specification.